HIGH IMPACT POLYSTYRENE

High Impact Polystyrene (HIPS) contains rubber (Butadiene) and is particularly useful in the manufacturing of parts which require a high degree of impact resistance. In our range, we have HIPS suitable for Refrigerators (stress cracking resistance grade), High Gloss grade for glossy surface finish applications.

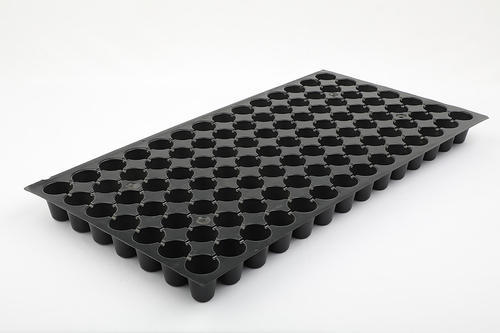

High Impact Polystyrene (HIPS) is generally used in the manufacturing of Refrigerator interiors, food trays & cups, electrical appliance components, TV and audio-visual equipment parts, automotive parts, toys, Instrument panels and fittings, gasoline tanks, computer housings, sheets & laminations, cutlery, medical appliances, fan parts, Air conditioner grills etc. Some major applications are:

| HIPS - Specification | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Typical Properties | ASTM Test | Units | HI-850 | HI-800 | HI-800 High Gloss |

HI-861 | HI-851 | HI-826 High Gloss |

||

| Tensile Strength | D-638 | Kgf/cm2 | 200 | 150 | 150 | 210 | 210 | 280 | ||

| Tensile Modulus | D-638 | Kgf/cm2 | 13000 | 12000 | 12000 | 12000 | 13000 | 14000 | ||

| Tensile Elongation | D-638 | % | 40 | 40 | 40 | 50 | 40 | 40 | ||

| Flexural Strength | D-790 | Kgf/cm2 | 375 | 300 | 300 | 400 | 400 | 500 | ||

| Flexural Modulus | D-790 | Kgf/cm2 | 17000 | 16000 | 16000 | 16000 | 17000 | 19000 | ||

| Izod Impact Resistance | D-256 | Kg-cm/cm | 10 | 11 | 11 | 11 | 10 | 12 | ||

| Gardner Falling Dart | D-5420 | In-lb | 95 | 113 | 113 | 113 | 95 | \139 | ||

| Vicat Softening Temperature | D-1525 | ℃ | 90 | 90 | 90 | 90 | 90 | 96 | ||

| Heat Deflection Temperature | D-648 | ℃ | 85 | 80 | 80 | 85 | 85 | 92 | ||

| Specific Gravity | D-792 | - | 1.04 | 1.04 | 1.04 | 1.04 | 1.04 | 1.05 | ||

| Gloss | D-523 | % | - | - | 70 | - | - | 80 | ||

| Melt Flow Index | D-1238 | gm/10min | 6 | 11 | 11 | 4 | 3 | 3.5 | ||

| Product Description | Injection Grade | Injection Grade | Injection Grade | Extrusion Grade | Extrusion Grade | Injection Grade | ||||

| Grades | Characteristics | Applications |

|---|---|---|

| HI-850 | High Impact, Standard Flow, Good Gloss, Low Volatility. | House Ware, Drinking Cups, Washing Machine Plastic Parts, Plastic Refrigerator Parts, Toys, Stationery Products, Sanitary Products, Plastic Hangers, Cotton Buds, Automotive Spare Parts and Disposable Razors etc. |

| HI-800 | High Flow, Superior Heat Characteristics, Better Mold Capability, Good Strength, Good Practical Toughness, Excellent Mold Release Behavior & Brilliant Process Ability Properties During Molding. | Containers for Cosmetic Products, Stationery Products, Disposable Cutlery, Plates, Glasses, Dairy Packaging Products and Disposable Lids etc. |

| HI-800 High Gloss | High Flow, Superior Heat Characteristics, Better Mold Capability, Good Strength, Good Practical Toughness, Excellent Mold Release Behavior & Brilliant Process Ability Properties During Molding. | Containers For Cosmetic Products, Stationery Products, Exhaust Fans Grills, Washing Parts and Sanitary Products etc. |

| HI-861 | High Impact, Good Gloss, Low Volatility, Stress Cracking Resistant (Freon Resistant). | Sheets and Lamination of Freezers and Deep Freezers, Plates, Glasses, Cups, Dairy Packaging Products and House Hold Items etc. |

| HI-851 | High Impact, Good Gloss, Low Volatility. | Disposable Cutlery, Plates, Glasses, Cups and Household Products, Seed Trays, Laminated sheets eg for EPS Pallet etc. |

| HI-861 High Gloss | Medium flow, Superior heat characteristics, Better mold capability, Good strength, Good practical toughness, Excellent mold release behavior, High Gloss. | Air conditioner grills, TV cabinets, Cosmetic packing parts, Stationery products and thick wall molding. |